Understanding the Role of Low Pressure Mixing Heads in Polyurethane Processing

4 min readPolyurethane has become one of the most versatile materials in the modern world, widely used across industries from automotive to furniture, insulation, footwear, and countless other applications. The performance of polyurethane products is deeply tied to the processing technologies that create them. One of the most critical components in this process is the mixing head. While high pressure mixing systems have their place, low pressure mixing heads remain an essential solution in many polyurethane production settings.

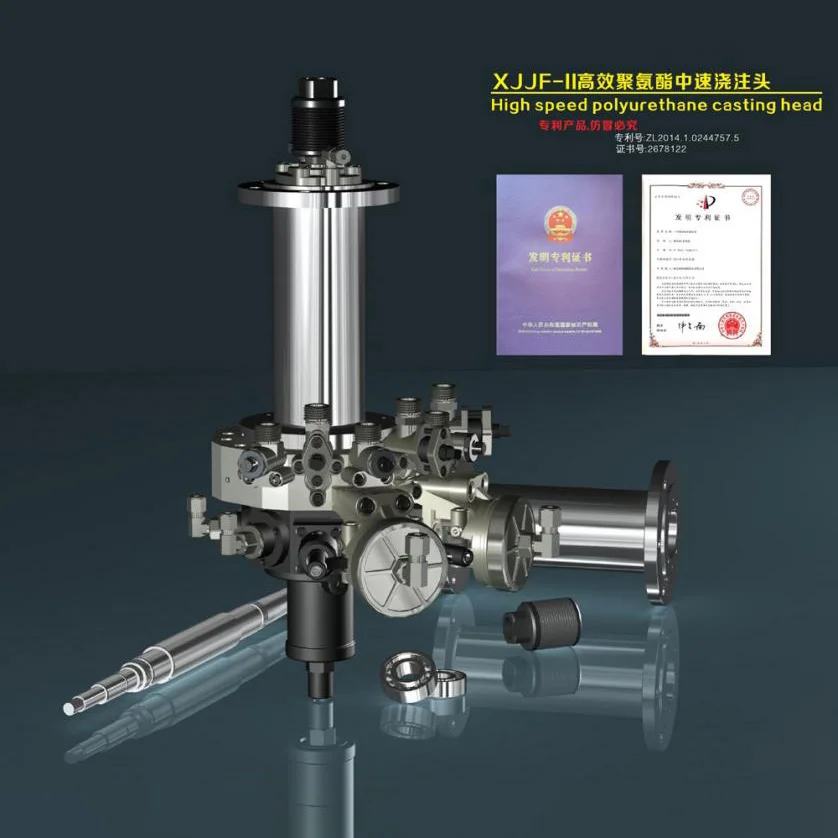

As one of the global leaders in polyurethane production and processing equipment, Haifeng has spent years developing advanced systems and machinery to support manufacturers around the world. Among their innovations, low pressure mixing heads stand out as a crucial part of ensuring quality, efficiency, and flexibility in polyurethane processing.

Importance of Mixing in Polyurethane Processing

Polyurethane is formed by the chemical reaction between polyols and isocyanates, often with additional additives such as catalysts, blowing agents, pigments, or stabilizers. For the material to achieve its full potential in strength, durability, and performance, the raw components must be mixed thoroughly and consistently. Poor mixing can result in uneven cell structures, weak mechanical properties, and defects in the finished products.

This is where the mixing head plays a vital role. It ensures that the components are blended precisely, maintaining the balance between chemical reaction speed, homogeneity, and output requirements. The right mixing head allows manufacturers to fine-tune formulations, achieve consistent quality, and meet specific application demands.

Characteristics of Low Pressure Mixing Heads

Low pressure mixing heads operate differently from high pressure systems. Instead of relying on the impact of high-velocity streams colliding within a mixing chamber, low pressure systems employ mechanical stirring or rotating elements to blend the components.

Some of the key characteristics include:

Mechanical Mixing Action: Low pressure mixing heads use a dynamic mixer, often a stirrer or impeller, to ensure uniform distribution of chemicals.

Gentle Processing: Because the system operates at lower pressures, the equipment experiences less wear and tear, extending service life and reducing maintenance requirements.

Versatility in Applications: These heads can handle a wide variety of polyurethane formulations, from rigid foams to flexible foams and elastomers.

Ease of Operation: Low pressure systems are generally simpler to use and maintain compared to high pressure counterparts, making them attractive for many manufacturers.

Cost Efficiency: Lower investment and maintenance costs can make these systems more accessible for small and medium-scale operations.

Applications Across Industries

Low pressure mixing heads are used in diverse polyurethane production lines. Some common applications include:

Furniture and Bedding: Producing flexible foam for cushions, mattresses, and seating.

Footwear: Creating lightweight yet durable soles and insoles.

Insulation: Manufacturing rigid foam panels and sprayed insulation materials for buildings.

Automotive: Developing interior components such as armrests, dashboards, and seating.

Elastomers and Coatings: Forming tough, resilient products for industrial applications.

Because of their adaptability, low pressure systems remain a trusted choice for manufacturers who need to balance performance with cost-effectiveness.

Advantages Brought by Haifeng’s Expertise

Haifeng has established itself as one of the world’s leading manufacturers of polyurethane production and processing equipment. The company’s low pressure mixing heads are designed with precision engineering, high-quality materials, and a focus on reliability.

Some of the distinguishing features of Haifeng’s solutions include:

Customized Designs: Tailored to meet specific client needs and application requirements.

High Precision: Ensuring consistent mixing quality and minimizing material waste.

Durability: Built for long service life with minimal downtime.

Global Support: Backed by extensive technical service and after-sales support across international markets.

By leveraging their expertise, Haifeng empowers manufacturers to enhance productivity while ensuring stable and reliable polyurethane processing.

Sustainability and Efficiency Considerations

Sustainability has become a central concern in modern manufacturing. Low pressure mixing systems, particularly when designed with energy efficiency in mind, can contribute to reduced energy consumption and lower material waste. The ability to control formulations precisely means manufacturers can optimize their processes, minimizing excess material usage and improving yield.

Haifeng’s innovations in this space reflect a commitment to helping the industry align with global sustainability goals without compromising on product performance.

The Role of Operator Training and Maintenance

Even with advanced equipment, the performance of low pressure mixing heads depends on proper operation and regular maintenance. Training operators to handle the machinery effectively ensures that every batch of polyurethane maintains consistent quality. Additionally, routine checks for wear, cleaning of the mixing chamber, and timely replacement of components help extend the lifespan of the equipment.

Haifeng supports its customers with training programs and detailed maintenance guidelines, enabling smooth day-to-day operations.

Why Low Pressure Mixing Heads Remain Indispensable

While high pressure systems are often associated with large-scale, high-volume production, low pressure mixing heads continue to hold an indispensable role in the industry. Their flexibility, reliability, and cost-effectiveness make them ideal for many polyurethane applications, especially where batch sizes are smaller or where specialized formulations are required.

Manufacturers benefit from the ability to produce a wide variety of polyurethane products without the need for extremely high investment or overly complex systems.

Conclusion

The polyurethane industry thrives on innovation, precision, and efficiency. Among the many technologies driving this sector, low pressure mixing heads remain a cornerstone for reliable processing. Their ability to provide consistent quality, reduce costs, and support diverse applications ensures their ongoing importance in production lines around the world.

With companies like Haifeng leading the way in polyurethane equipment and system manufacturing, the industry continues to benefit from advancements that improve productivity, sustainability, and overall product quality. For manufacturers looking to strengthen their operations, understanding the role of low pressure mixing heads is essential to achieving long-term success.

Low Pressure Foaming Machines: Common Applications Across Industries

www.haifeng-automation.cn

Haifeng