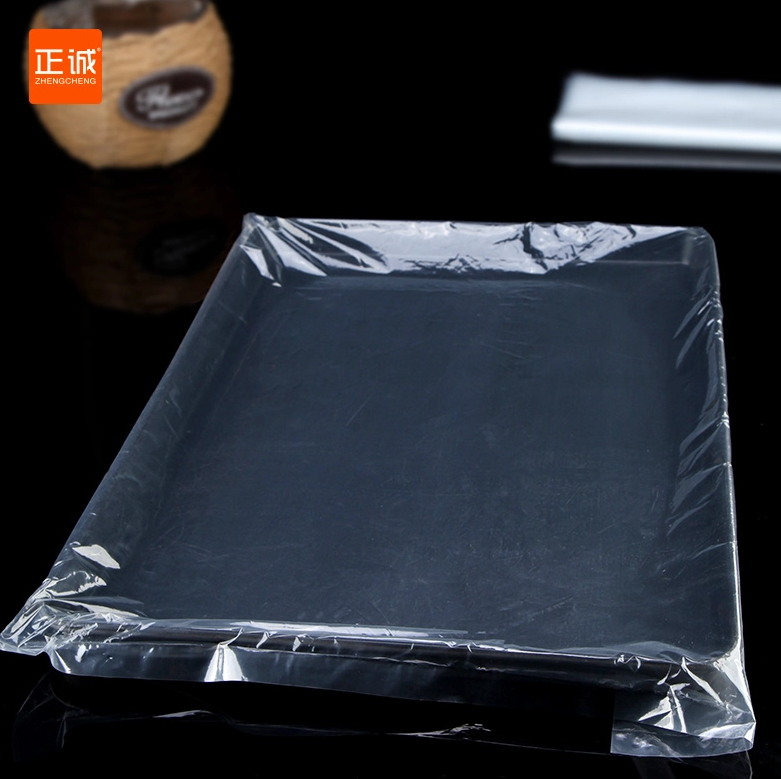

PE, CPP, or Laminated Film? Material Differences That Matter for Baking Pan Bags

4 min readIn commercial baking, the right packaging material can make or break product quality, shelf life, and customer satisfaction. For baking pan bags, material choice directly affects heat resistance, sealing strength, durability, and product presentation. Selecting the wrong material can lead to deformation, product spoilage, or poor shelf appeal.

Zhengcheng Packaging, with over a decade of experience in packaging design, production, and baking technology training, provides high-performance solutions to over 130 countries. This article explores how PE, CPP, and laminated films perform in real baking applications and provides actionable strategies for selecting the optimal material for your baking pan bags.

1. Performance Differences in Real Baking Applications

1.1 Heat Resistance

-

CPP and laminated films outperform PE in high-temperature processes such as hot-fill or post-baking packaging.

-

PE can deform under heat, making it unsuitable for products packaged immediately after baking or for microwaveable applications.

-

Laminated films can be customized to endure higher temperatures while maintaining structural integrity.

1.2 Moisture and Gas Barrier

-

PE provides excellent moisture protection but limited oxygen barrier.

-

Laminated films excel in both moisture and oxygen barriers, critical for longer shelf life and for preventing staling in premium baked goods.

-

CPP alone offers moderate barrier properties; combining it with lamination can achieve near-laminate-level performance.

1.3 Mechanical Strength

-

Tear and puncture resistance is crucial during transport.

-

Laminated films deliver the highest durability, followed by CPP; PE is flexible but more prone to punctures when handling dense or heavy bakery products.

-

Bags for heavy loaf cakes or multiple stacked pastries benefit most from laminated constructions.

1.4 Appearance and Branding

-

Transparency and gloss affect consumer perception.

-

CPP and laminated films provide high clarity and gloss for attractive product presentation.

-

PE is adequate for functional packaging but less suitable for premium branding where visual appeal drives sales.

2. Selecting the Right Material Based on Product Type

| Product Type | Recommended Material | Reason |

|---|---|---|

| Soft pastries | PE | Flexible, cost-effective, sufficient moisture protection |

| Hot-packaged baked goods | CPP | Heat resistance, excellent seal strength, high clarity |

| Long-shelf-life products | Laminated Film | Superior barrier, puncture resistance, premium branding |

| Heavy or dense cakes | Laminated Film | High mechanical strength prevents tearing or deformation |

| Display products requiring high visibility | CPP / Laminated Film | Glossy and transparent to enhance shelf appeal |

By matching product type to material performance, bakeries can reduce spoilage, maintain freshness, and enhance presentation.

3. Cost vs. Performance Trade-Off

-

PE is the most cost-effective, suitable for high-volume, low-margin items.

-

CPP offers a balance between heat resistance and appearance at a moderate price.

-

Laminated films are premium materials; while more expensive, they reduce waste and enhance brand perception, often resulting in higher ROI for specialty products.

A strategic approach involves assessing product requirements, packaging volume, shelf life, and consumer expectations to choose the most suitable material.

4. Handling and Processing Considerations

-

Automated Packaging: CPP and laminated films handle well in high-speed machinery; PE may require reinforcement to prevent jams.

-

Sealing Performance: Heat sealing varies with material; CPP and laminated films allow robust seals under moderate to high temperatures.

-

Storage and Stability: Laminated films maintain structural integrity under varying humidity and temperature conditions, reducing spoilage during transport.

-

Customization: Laminated films can be engineered for microwaveable bags, hot-fill baking, or barrier-specific applications.

5. Advanced Strategies for Material Optimization

5.1 Layer Combination

-

Laminated films allow combining PE, PET, BOPP, and other layers to achieve custom barrier, heat, and mechanical properties.

-

Bakers can optimize for transport durability, heat resistance, or visual appeal depending on product needs.

5.2 Seal Testing

-

Implement batch-wise seal testing for high-speed production lines to ensure uniformity across PE, CPP, and laminated film bags.

-

For laminated constructions, proper lamination quality ensures both barrier performance and mechanical strength.

5.3 Shelf-Life Validation

-

Test each material under real-world storage conditions.

-

Laminated films can extend shelf life substantially compared to single-layer PE or CPP, particularly for products sensitive to oxygen or moisture.

5.4 Branding and Printing

-

Laminated films support high-resolution printing, embossing, and multi-color designs, enhancing brand recognition.

-

CPP allows glossy finishes, ideal for visibility-focused products.

-

PE is functional but less suitable for premium marketing packaging.

6. FAQ: Material Selection for Baking Pan Bags

Q1: Can I use PE for hot-fill baked goods?

A: PE alone is not recommended for hot-fill applications due to deformation risk. CPP or laminated films are more suitable.

Q2: Are laminated films always better than CPP?

A: Not necessarily; laminated films offer superior barrier and mechanical strength but at higher cost. CPP may suffice for products with shorter shelf life or moderate handling requirements.

Q3: How do I choose between CPP and laminated film for medium-weight baked goods?

A: Consider shelf-life requirements, heat sealing needs, and desired appearance. If extended shelf life or premium look is required, laminated films are preferred.

Q4: Does material affect automated packaging line speed?

A: Yes. CPP and laminated films are generally compatible with high-speed machines. PE may need adjustment or reinforcement to prevent jams.

Q5: Can laminated films be customized for microwaveable packaging?

A: Yes. Layer composition and lamination techniques can be optimized for heat resistance and safety in microwave applications.

7. Conclusion

Choosing the right material for baking pan bags is a strategic decision that directly impacts product quality, shelf life, and brand perception. By evaluating heat resistance, barrier properties, mechanical strength, and visual appeal, bakeries can optimize packaging for both functional performance and marketing impact.

Zhengcheng Packaging, with its expertise in packaging design, R&D, and baking technology, offers tailored solutions using PE, CPP, and laminated films to meet diverse product requirements. By carefully matching material properties to product type and processing needs, bakeries can achieve enhanced freshness, superior presentation, and reduced waste, ultimately delivering a better experience to consumers.

www.szzcbz.com

Suzhou Zhengcheng Packaging & Equipment Co., Ltd.