Unleashing the Potential: Exploring the Feasibility of 3D Printing Wood

2 min read

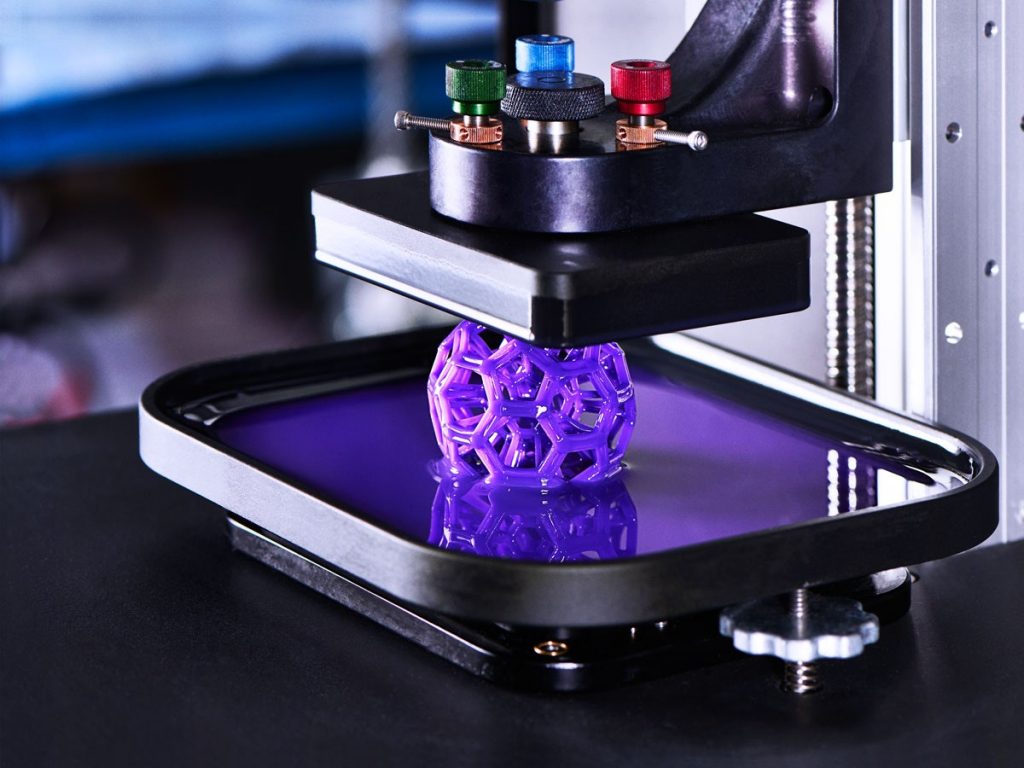

In recent years, 3D printing has revolutionized manufacturing processes across various industries. From plastic prototypes to metal components, this technology has pushed the boundaries of what is possible. However, one question remains: Can a 3D printer print wood? In this article, we delve into the fascinating world of additive manufacturing and explore the feasibility, challenges, and potential applications of 3D printing with wood.

- The Basics of 3D Printing:

To understand the potential of 3D printing wood, let's first grasp the fundamentals of this innovative technology. 3D printing, also known as additive manufacturing, involves creating three-dimensional objects by layering materials based on a digital model. Traditional 3D printers use plastic filaments or metal powders, but advancements have paved the way for exploring new materials, including wood. - The Challenge of Printing Wood:

Wood, being an organic and fibrous material, presents unique challenges when it comes to 3D printing. Unlike plastics or metals, wood has inherent grain patterns, varying densities, and moisture content. These properties make it difficult to achieve the desired structural integrity and surface finish. However, researchers and engineers are actively working on overcoming these obstacles. - Wood Filaments and Composite Materials:

To print with wood, specialized filaments or composite materials are used. Wood filaments typically consist of a mixture of recycled wood fibers and a binding agent, such as PLA (polylactic acid). These filaments mimic the appearance and texture of wood, allowing for the creation of intricate designs and functional objects. - Preparing Wood for 3D Printing:

Before printing with wood, proper preparation is crucial. The wood filament needs to be dried thoroughly to minimize moisture content, which can affect print quality. Additionally, adjusting printer settings, such as temperature and extrusion rate, is necessary to achieve optimal results. Calibration and experimentation play a significant role in obtaining the desired print quality. - Applications of 3D Printed Wood:

The ability to 3D print with wood opens up a world of possibilities. Here are a few potential applications:

- Art and Design: Artists and designers can leverage 3D printing to create intricate wooden sculptures, furniture, and decorative objects with unique shapes and patterns.

- Architecture: 3D printed wooden models can aid architects in visualizing and prototyping complex structures, enabling more efficient and sustainable building practices.

- Education: 3D printing wood can enhance educational experiences by allowing students to explore woodworking concepts and create custom wooden models for various subjects.

- Sustainable Manufacturing: By utilizing recycled wood fibers and reducing waste, 3D printing with wood aligns with sustainable manufacturing practices, contributing to a greener future.

Conclusion:

While 3D printing wood presents challenges, ongoing research and development are pushing the boundaries of this technology. With the right materials, preparation, and expertise, it is indeed possible to print with wood. The applications of 3D printed wood span various industries, offering new avenues for creativity, sustainability, and innovation. As technology continues to advance, we can expect further breakthroughs in the realm of additive manufacturing, unlocking the full potential of 3D printing with wood.