The Inner Workings of a Balanced Seal: Understanding How It Works

2 min read

A balanced seal is a critical component in many industrial applications, including pumps, compressors, and turbines. It is designed to prevent leakage of fluids or gases from the high-pressure side of the system to the low-pressure side. In this article, we will explore the inner workings of a balanced seal and how it works to maintain a tight seal.

What is a Balanced Seal?

A balanced seal is a type of mechanical seal that uses a series of springs and other components to maintain a balance between the pressure on the high-pressure side and the low-pressure side. The seal is designed to prevent fluid or gas from leaking out of the system, while also preventing contaminants from entering the system.

How Does a Balanced Seal Work?

A balanced seal works by using a series of springs and other components to maintain a balance between the pressure on the high-pressure side and the low-pressure side. The seal is designed to prevent fluid or gas from leaking out of the system, while also preventing contaminants from entering the system.

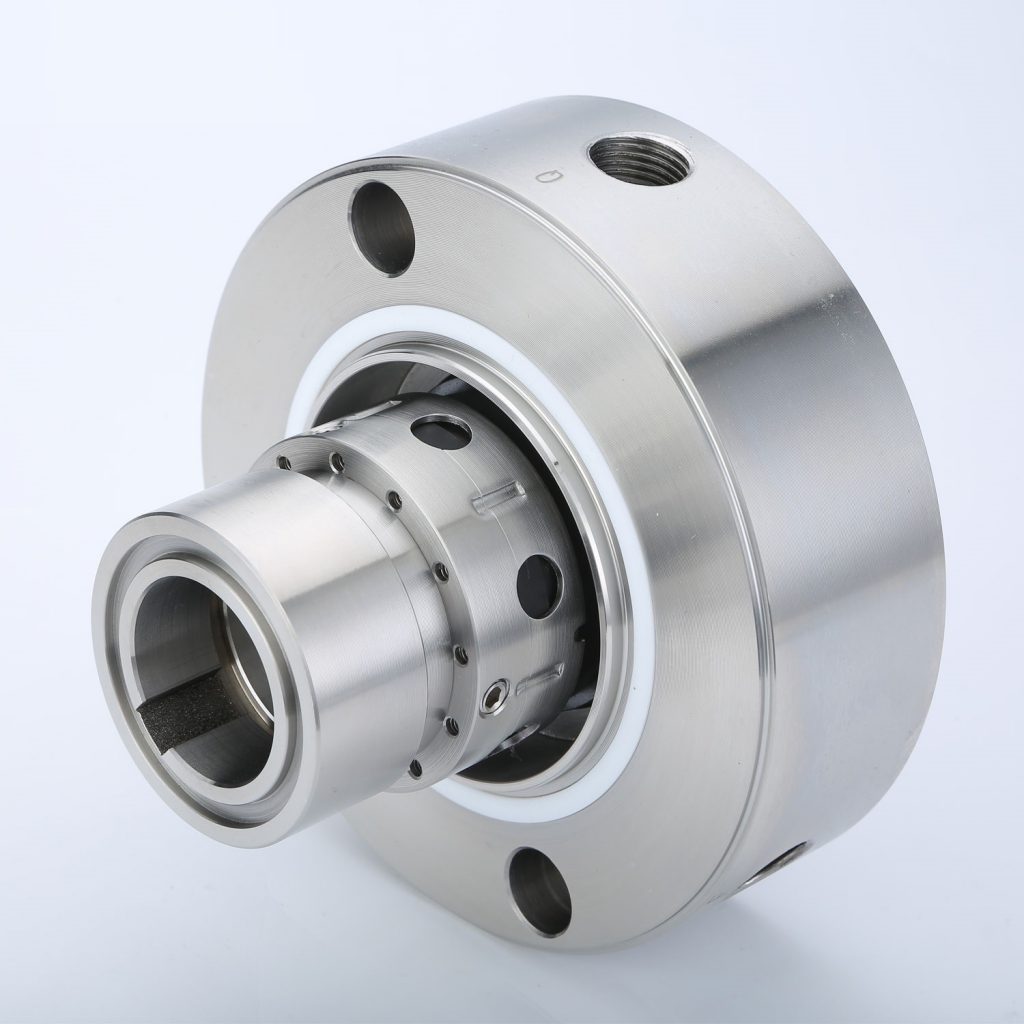

The seal consists of two main components: the stationary component and the rotating component. The stationary component is typically mounted on the pump or compressor housing, while the rotating component is mounted on the shaft. The two components are separated by a small gap, which is filled with a sealing fluid.

As the shaft rotates, the sealing fluid is forced through the gap between the two components, creating a barrier that prevents fluid or gas from leaking out of the system. The springs and other components in the seal help to maintain a balance between the pressure on the high-pressure side and the low-pressure side, ensuring that the seal remains tight and effective.

Advantages of a Balanced Seal:

One of the main advantages of a balanced seal is that it is designed to maintain a tight seal even under high-pressure conditions. This makes it ideal for use in applications where leakage can be a significant problem, such as in pumps, compressors, and turbines.

Another advantage of a balanced seal is that it is relatively easy to install and maintain. The seal can be easily replaced when it wears out, and it requires minimal maintenance to keep it functioning properly.

Conclusion:

In conclusion, a balanced seal is a critical component in many industrial applications, and it plays a vital role in preventing leakage of fluids or gases from the high-pressure side of the system to the low-pressure side. By understanding how a balanced seal works, you can ensure that your system remains leak-free and operates efficiently.