Understanding the Differences Between Rotating and Stationary Seals

2 min read

Seals are an essential component in many industrial applications, including pumps, compressors, and turbines. They are used to prevent the leakage of fluids and gases from the equipment. There are two main types of seals: rotating and stationary. In this article, we will explore the differences between these two types of seals and their applications.

Rotating Seals:

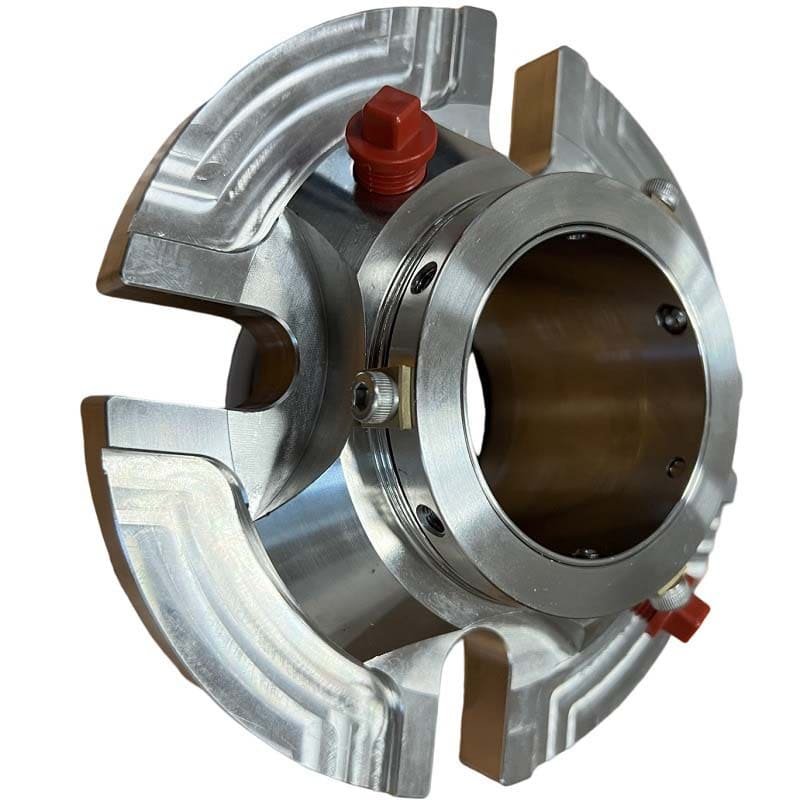

Rotating seals are designed to rotate with the shaft of the equipment. They are commonly used in applications where the shaft is rotating at high speeds, such as in centrifugal pumps and compressors. The primary function of a rotating seal is to prevent the leakage of fluids and gases from the equipment while allowing the shaft to rotate freely.

One of the key advantages of rotating seals is that they can handle high speeds and pressures. They are also less prone to wear and tear compared to stationary seals. However, rotating seals require lubrication to prevent overheating and premature failure.

Stationary Seals:

Stationary seals, on the other hand, are fixed in place and do not rotate with the shaft. They are commonly used in applications where the shaft is stationary, such as in reciprocating pumps and compressors. The primary function of a stationary seal is to prevent the leakage of fluids and gases from the equipment while maintaining a fixed position.

One of the key advantages of stationary seals is that they are less complex and easier to install compared to rotating seals. They also require less maintenance and are less prone to failure. However, stationary seals are not suitable for high-speed applications and may wear out faster than rotating seals.

Applications:

The choice between rotating and stationary seals depends on the specific application and operating conditions. Rotating seals are typically used in high-speed applications, while stationary seals are used in low-speed applications. Some common applications of rotating seals include centrifugal pumps, compressors, and turbines, while stationary seals are commonly used in reciprocating pumps and compressors.

Conclusion:

In summary, rotating and stationary seals are two types of seals used in industrial applications to prevent the leakage of fluids and gases from equipment. Rotating seals are designed to rotate with the shaft and are suitable for high-speed applications, while stationary seals are fixed in place and are suitable for low-speed applications. The choice between these two types of seals depends on the specific application and operating conditions. By understanding the differences between rotating and stationary seals, engineers can make informed decisions when selecting the appropriate seal for their application.